|

OCR (Optical Character Recognition) and WMS (Warehouse Management System) are two distinct technologies that, when integrated, can significantly enhance the efficiency and accuracy of warehouse operations.

Other advantages will be that you can use OCR when products come into the warehouse without a barcode. In a manufacturing environment you can use it to capture temperature in the production environment such as temperature of the tanks. In summary, the integration of OCR and WMS creates a powerful synergy, automating data capture and processing tasks within the warehouse. This not only improves operational efficiency but also enhances accuracy and traceability, contributing to overall supply chain optimisation. Silvan Australia Case Study11/12/2023 The RIC Group's implementation of our Warehouse Management Solution at Silvan Australia has yielded immediate returns on investment, particularly in production, through streamlined operations. This comprehensive solution spans all facets and locations of the business, showcasing a scalable freight integration via REST API and a notably improved user interface tailored for Android devices. The successful deployment across the organisation signifies a significant milestone in optimising operations and enhancing efficiency. Acumatica Summit 20241/12/2023 The RIC Group's Warehouse Management Solution will be at the Acumatica Summit 2024 at our distributors stand Linfa Systems.

Acumatica Summit 2024 will take place starting Sunday, January 28 through Wednesday January 31 with three full days of expanded opportunities to network, to connect, to learn, to train, to celebrate and to discover. 2023 End of Year closure20/11/2023 It's been a year of growth and expansion here at The RIC Group and we would like to thank you for being part of the journey. We look forward to working with you next year and making 2023 a success.

Merry Christmas, Happy Holidays! The entire team at The RIC Group would like to thank you for your support and we wish you all the best for the holiday season. Office Closure & Support Our offices will be closed from Close of Business Thursday 21st of December 2023. We will resume normal business hours on Monday the 8th of January 2024. There will be a skeleton team in place to attend support during this period and the best way to access support is to email support@thericgroup.com or call us on Phone: +61 478 113 932 Look forward to working with you again in the New Year. DHL Integration17/11/2023 The RIC Group's supply chain solution achieves DHL Integration. This allows our customers who are using DHL to have integrated WMS solution with DHL. This integration allows customers to create consignments for DHL local and overseas.

Visit here for more information on the DHL API. RFID in the warehouse15/11/2023 RFID technology has emerged as a valuable asset in optimizing supply chain management processes. Its ability to provide real-time visibility, automate data capture, and enhance accuracy has positioned it as a key enabler for efficient operations. With RFID, companies can streamline inventory management by tracking products throughout the supply chain, enabling better control over stock levels and reducing the risk of errors associated with manual tracking. The automated nature of RFID not only accelerates processes such as receiving and shipping but also contributes to minimizing shrinkage and loss through precise, real-time monitoring. Additionally, RFID facilitates efficient traceability, supporting compliance with regulations and providing crucial data for quality control.

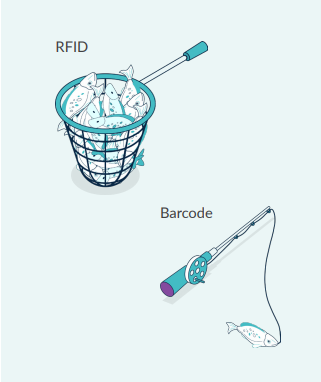

The analogy of fishing with a rod versus using a net effectively captures the essence of the differences between RFID and barcodes. Barcodes, akin to fishing with a rod, involve the sequential scanning of individual items, much like catching one fish at a time. On the other hand, RFID, likened to scooping all the fish up in a net, allows for simultaneous reading of multiple items, offering advantages in terms of speed and efficiency. Importantly, the decision to use RFID or barcodes isn't always a strict either-or scenario. There are numerous situations where a combination of both technologies can be employed to create a more versatile and effective solution. Barcodes, with their simplicity and established systems in various industries, are well-suited for applications that don't demand simultaneous scanning. However, their reliance on a direct line of sight can be a limitation. In contrast, RFID shines in scenarios requiring bulk reading, non-line-of-sight capabilities, or real-time tracking. The ability to read multiple tags at once and the flexibility in reading through obstacles make RFID ideal for applications where efficiency and visibility into large quantities of items are crucial. The RIC Group builds solutions which allow the combining of both technologies. This strategically can leverage the strengths of each, providing a comprehensive solution to diverse operational requirements. Please contact us to find out more. Consistency Breeds Efficiency3/11/2023 Prospects will often tell us the flexibility the Supply Chain Software will need to have to meet their requirements. Often this happens when the customer has been using one software package for an extended period of time, and have bolted on customisations to suit their needs at that time

Fulfilling B2C orders in one manner, B2B orders differently, and handling priority orders through separate processes might seem accommodating at first glance. However, this approach often results in a tangled web of processes. Instead of facilitating a streamlined system, it leads to confusion, increased complexity, and inefficiency within the supply chain software. For me the strategy always has to be standardise the process. Establishing standard processes offers a multitude of benefits. Consistency is the cornerstone of success. Implementing standardised processes ensures that tasks are performed in the same way every time. This uniformity streamlines operations, minimizes errors, and reduces the need for reinventing the wheel with each new project. When employees follow a set structure, it becomes easier to identify bottlenecks, address inefficiencies, and optimize workflow. There are other benefits such as making training and onboarding simplified, gives you scalability and assists with compliance to reduce risk. Consistent processes form the backbone of efficiency, quality and reliability within an organisation. Catch Weight30/10/2023 Catch weight management is a crucial aspect for companies dealing with variable-weight items, especially in food distribution or industries where product weight fluctuates. The system allows for the tracking of both an average per item quantity/weight as well as an actual per item quantity/weight. To simplify, catch weight management involves the identification and tracking of both average and actual per-item quantities or weights. This method is essential for effectively managing business processes, particularly when handling variable weight units of a product. Example Scenario:

This system enables accurate invoicing, inventory control, and cost management by considering both the average and actual weights of variable items. It ensures fair and accurate billing, minimising discrepancies between estimated and actual quantities, and ultimately enhances customer satisfaction. Businesses dealing with products that vary in weight and require invoicing based on the actual weight rather than a fixed quantity or package count find catch weight management vital. This approach is especially common in industries where the actual weight of a product determines its final price or cost. It allows for a more accurate and fair billing process, ensuring that customers are charged based on the exact weight they receive rather than an estimated or average weight. Absolutely, implementing a Warehouse Management Solution (WMS) for accurately capturing catch weight items on the warehouse and factory floor is a game-changer for businesses dealing with variable-weight products. You can use the WMS to scan LPN (Licence Plate Numbering) as well which will capture all cartons and the weight on the pallet with an instance scan of the barcode. The process of manually capturing weight, batch, expiry dates, carton counts, and other specifics for each item picked is not only error-prone but also incredibly time-consuming. Without an automated system, the potential for errors significantly increases, and the manual effort involved in tracking and inputting this data can slow down warehouse operations. A WMS streamlines this process by automating the data capture through scanning GS-128 barcodes and more. As each carton or pack is scanned, the system automatically records vital information such as weight, batch numbers, expiry dates, carton counts, and the precise weight of the items picked. This data is then seamlessly transferred to the ERP system, ensuring accurate invoicing and streamlined operations. The efficiency gained by using a WMS not only minimizes errors but also accelerates warehouse processes. The ability to swiftly and accurately capture data, especially for catch weight items, ensures precise invoicing and enhances customer satisfaction. The use of automated technology significantly reduces the margin for error and ensures that customers are billed accurately based on the exact products received, thereby improving trust and reliability. Please contact us for further information. Status Quo23/10/2023 In our company, The RIC Group, our Supply Chain Solution is now in its fourth generation, and we've been successfully implementing Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) for over two decades. Implementing a WMS can significantly enhance efficiency and labour optimization, ensuring a business's ability to scale.

So, why do many businesses continue with the status quo? Surprisingly, the discussions I had with potential clients 20 years ago are strikingly similar to those I have today when visiting new prospects. The majority of these prospects are still relying on paper-based processes, and their warehouse operations remain entirely manual. It's a common scenario, regardless of a business's size or revenue. The question often asked by these prospects is, 'What exactly are we getting here?' Change can be a daunting prospect, especially in the world of business. The status quo represents a comfortable and safe zone, leading business owners to ask, 'Why fix something that isn't broken?' I frequently hear, 'We know our current processes are inefficient, but they get the job done.' When selling software, there's often a fear of loss, where prospects worry about technical performance or the monetary investment required. In my view, the status quo is essentially 'cost-to-delay.' Sticking to outdated processes incurs hidden costs, leading to decreased productivity, missed opportunities, and errors. The status quo negatively impacts efficiency, effectiveness, and overall productivity, hindering a business's growth potential. Recently, I revisited a couple of our customers who were initially hesitant to implement a WMS. However, as we began to implement the Warehouse Management Solution, they quickly embraced the disruption when they witnessed immediate return on investment and the removal of inefficiencies. One of our customers shared that it used to take them three days to ship an order, but now they manage same-day shipments thanks to the scalable process provided by the WMS. Moreover, the volume of orders has naturally increased because customers now trust that their orders will arrive promptly. For this customer using our last-mile delivery, the moment orders are picked, consignment labels are generated and applied to the pallets, eliminating the inefficiency of waiting for freight labels, manual data entry, and ERP updates. This alone saved the customer two hours of labour each day, equating to 20 hours per week and close to 1,000 hours per year. Both customers reported that, over the last 15 years, the most significant return on their investment in technology was the Warehouse Management Solution. The efficiency gains alone justified the investment within the first year. They emphasized that this return on investment far exceeded what they experienced with ERP system upgrades, often considered the more phased approach to IT projects. I encourage businesses not to focus on what they are 'buying,' but rather to embrace disruption. Failing to do so essentially results in buying into a 'cost-to-delay' scenario. Contact Paul on his email to talk further. |

Archives

April 2024

|

Call Us: +61 466 368 934

- Home

-

Solutions

-

Advanced Logistics

>

- Advanced Logistics for Acumatica

- Advanced Logistics for SAP Business One

- Advanced Logistics for Odoo

- Advanced Logistics for Netsuite

- Advanced Logistics for Business Central

- Advanced Logistics for Sage Intacct

- Advanced Logistics for MYOB Advanced

- Advanced Logistics for MYOB EXO

- Advanced Logistics for S/4 HANA

- Advanced Logistics for Sage 300

- Advanced Logistics for Tencia

- Advanced Logistics for Oracle Cloud ERP

- Transport Management System

- Last Mile Delivery

- Warehouse 3D Digital Twin

- RFID

- AUTONOMOUS MOBILE ROBOTS

-

Advanced Logistics

>

- Support

- Blog

- Success Stories

- About

- Contact Us