Solution Build25/9/2023 In today's fast-paced business world, finding effective solutions to complex problems is crucial for success. The process of solution building involves more than just identifying issues; it's about transforming challenges into opportunities and ideas into action. Let's delve into the art of solution building and explore the steps that can help you turn your vision into reality.

In conclusion, solution building is a dynamic process that requires creativity, collaboration, and adaptability. By following these steps and embracing a problem-solving mindset, you can turn challenges into opportunities. Remember, the most effective solutions often emerge from a blend of innovation, determination, and a commitment to making a positive impact. Our team recognizes that our work often involves creating solutions that encompass multiple processes within the supply chain, particularly concerning the flow of stock in and out of our customers' warehouses. It's common for each customer to have unique approaches to tasks like managing back orders. Additionally, we understand that every ERP solution may have distinct configurations to cater to the specific needs of each customer. Absolutely, it's essential for customers to recognize that their requirements can evolve, especially when dealing with dynamic environments such as supply chain management. From our experience the most successful customers foster an environment of adaptability and a willingness to accommodate evolving requirements, which allows customers to harness the full potential of their supply chain software to drive business growth and efficiency. Sage Intacct WMS and certification11/9/2023 The RIC Group pushes the boundaries with TBO4 and becomes the first certified Supply Chain Solution for Sage Intacct in Australia. Our WMS and TMS now allows Sage Intacct users to further extend the product with our best of breed WMS and TMS.

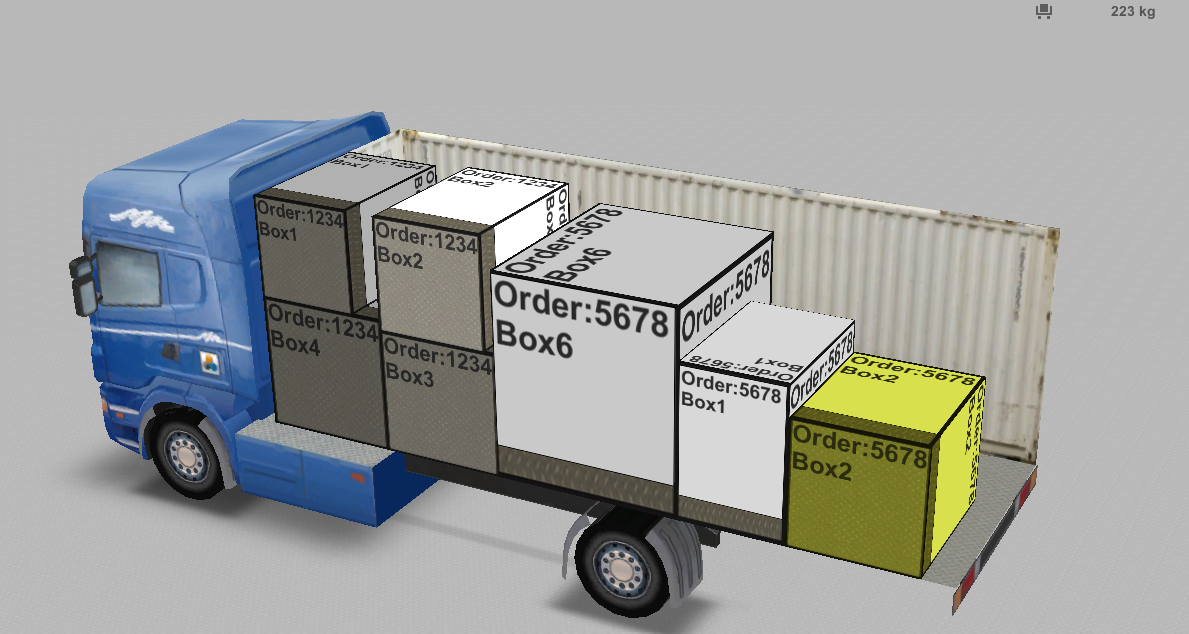

Please visit the Sage Intacct Marketplace to see our certified supply chain solution. 3D load planning6/9/2023 Our supply chain solution TBO4 integrates with EasyCargo a 3D loading software. Easy visualisation with your load plan in 3D and integration with TBO4. With the TBO4 integration it allows users to complete the Run Management process, complete the sequence and route optimisation and then use the Load Truck feature for the 3D Load Plan. Sending the pallet and carton information to EasyCargo then allows the user to quickly click on load to help create load plans quickly. The entire load plan result is shown in an interactive 3D view. The loading also allows for priority groups that sorts the cargo items based on final destination. You can define your vehicles or containers and even pallets. Gives you a step by step load report which is accessible by TBO4 our Warehouse Management Solution. You can verify weight distribution compliance with permitted limits. Please feel free to email our team for further information. Watch the video below to see how the product can help your business load more efficiently. Foodpro 202331/7/2023 The days were jam packed for Foodpro 2023 with a multitude of key decision makers paying visit to The RIC Group stand. We were run off our feet with invaluable contacts made and I have no doubt we will be able to secure future business from being an exhibitor. There were over 400 exhibitors with constant foot traffic. One of our successful points was showing our innovation of the 3D reporting. Our solutions help productivity for all businesses that need to implement a Warehouse Management Solution and Transport Management Solution. Please email us for further information. Foodpro - Melbourne 202317/7/2023 23 - 26 July, Melbourne Convention and Exhibition Centre

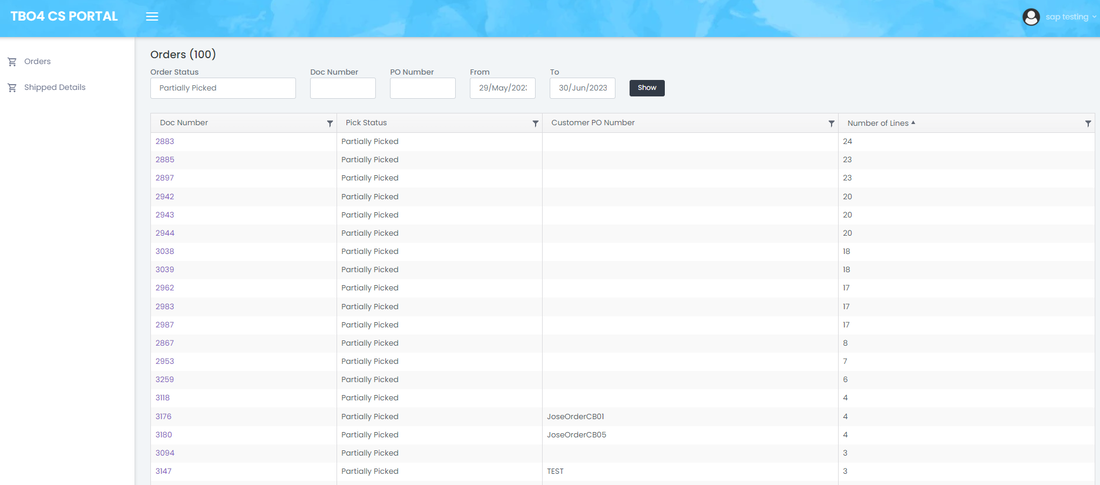

For over 50 years, Foodpro has gathered the industry to celebrate the contribution of Australian food produces, distributors and manufacturers. We are thrilled to announce that The RIC Group will be exhibiting at the highly anticipated Foodpro exhibition, the ultimate gathering for all food and beverage industry professionals. Please visit Th RIC Group on stand W11 where you can see our WMS and TMS and see our latest solutions of our Customer Portal and 3D Digital Twin. All-in-One SUpply Chain Solution29/6/2023 Our Supply Chain Solution TBO4 has always had a Warehouse Management Solution and Transport Management Solution. The latest addition to TBO4 is the Customer Service Portal.

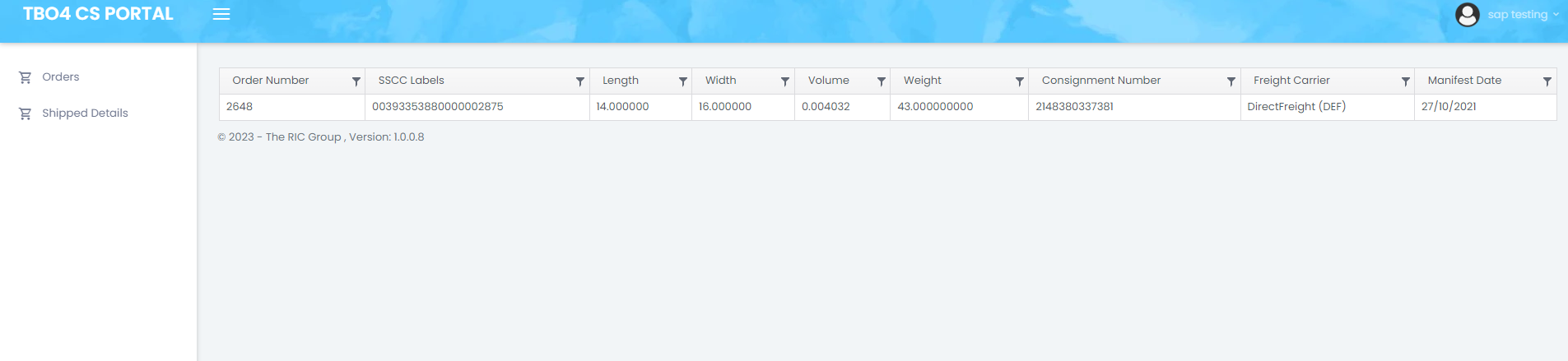

The customer service portal is great for the customer service team. It is an easy to use portal to get a current status of Sales Orders in the warehouse. Check to see if the order is released to the warehouse, or in the picking, or in the packing or being shipped stages. From here the other part is if the order is shipped, you can easily see the consignment number and who the freight provider is. There is more detail as well you can see the SSCC / cartons that were shipped and the L x W x H and weight. Easy to access and also available for sales people to access as well for their customers while on the road. A great part of the customer service portal is the information is so easy to view. There are filters of order status, the user can select a date or the user can easily enter in the sales order number from the ERP and have it displayed. Please contact us at sales@thericgroup.com if you would like more information on our All-in-one supply chain solution. Adapt to the challenge8/6/2023 All Round Supplies is a niche supplier which requires advanced kitting for their customer service. A large amount of customisation was required and during the deployment The RIC Group provided a high level of flexibility. Another customer who wishes they put in the Warehouse Management Solution from The RIC Group earlier. All Round Supplies Success Story25/5/2023 All Round Supplies went live with TBO4 our Warehouse Management Solution and the return on investment was immediate. Reduction in manual data entry which has resulted in a 20% increase in productivity. Watch the video below and see more of the feedback. RDP Client and Security21/4/2023 Our Supply Chain Solution does not use an RDP Client for Windows nor does it use Telnet which is a virtual terminal emulator. TBO4 from The RIC Group is developed in modern technology and is all browser based.

If you are using an RDP Client then you should ensure it is the latest version. The issue which we see all the time with RDP Client on Android is that the warehouse user scans barcodes and the barcode isn't transmitted to the WMS Software. Can you imagine deploying a Warehouse Management Solution in your warehouse which totally relies on scanning barcodes and these barcodes being dropped off because of the RDP Client? This wouldn't fit any purpose of WMS. The other issue which happens using RDP Client is that on occasions barcodes can carry special characters. This happens all the time with QR Barcodes (2D) and also happens quite a lot if customers use their own barcodes which are alpha numeric. An issue which commonly occurs is that using the RDP Client special characters from the barcode will drop and not transmit. As a business deploying a Supply Chain Solution these are simply risks you can't take. The next question to ask is about Android version of the RF Scanners or Tablet devices you are using. Your WMS and TMS software needs to support the latest Android versions such as Android 12 and 13. If it doesn't you are letting a security risk into your business. With our Supply Chain Solution there is a domain name and SSL for security purposes. On top of this we use OAuth 2.0 and OTP. The next part of security for our solution is we are implementing Google Authenticator. This will allow us to implement TOTP. Please let us know if you would like further information by emailing our team at sales@thericgroup.com Attention all Small and Medium Enterprises (SMEs) enthusiasts! The highly anticipated SAP Conference is just around the corner, and we couldn’t be more excited to share this incredible opportunity with you. If you’re passionate about Small and Medium Enterprises (SMEs), there’s no better place to be than at the SAP Conference in stunning Panama City.

The SAP Conference 2023 will be held in Panama City from May 23rd to May 25th. Please visit our North American partner Linfa Systems in our booth at the SAP conference. One of The RIC Group's team will also be on the stand to talk further about the road map of our WMS and TMS Solution for SAP. Register for the conference here. |

Archives

April 2024

|

Call Us: +61 466 368 934

- Home

-

Solutions

-

Advanced Logistics

>

- Advanced Logistics for Acumatica

- Advanced Logistics for SAP Business One

- Advanced Logistics for Odoo

- Advanced Logistics for Netsuite

- Advanced Logistics for Business Central

- Advanced Logistics for Sage Intacct

- Advanced Logistics for MYOB Advanced

- Advanced Logistics for MYOB EXO

- Advanced Logistics for S/4 HANA

- Advanced Logistics for Sage 300

- Advanced Logistics for Tencia

- Advanced Logistics for Oracle Cloud ERP

- Transport Management System

- Last Mile Delivery

- Warehouse 3D Digital Twin

- RFID

- AUTONOMOUS MOBILE ROBOTS

-

Advanced Logistics

>

- Support

- Blog

- Success Stories

- About

- Contact Us