Why a Phased WMS Approach with TBO4 Delivers Faster ROI

In warehouse and distribution operations, the biggest cost risk is rarely choosing the wrong Warehouse Management System (WMS). More often, it’s choosing to do nothing.

At The RIC Group, we see this regularly. Businesses delay WMS investment because operations are “coping,” volumes are manageable for now, or they believe a full WMS rollout must be a large, disruptive, all-or-nothing project. In reality, this hesitation quietly costs far more than moving forward with a phased implementation of TBO4.

Doing nothing Is not free

When a warehouse stands still, the business does not.

Order volumes increase, customer expectations tighten, labour costs rise, and manual processes are pushed beyond their limits. Without a modern WMS, these pressures show up as:

- Growing reliance on spreadsheets and workarounds

- Increasing labour hours and overtime

- Picking, packing, and dispatch errors

- Poor inventory visibility and accuracy

- Missed service levels and customer dissatisfaction

These costs rarely appear as a single budget line item—but over time they compound, directly impacting margin, scalability, and customer retention.

The Big Myth: You must implement everything at once

One of the main reasons businesses delay is the belief that a WMS must be deployed in one large, high-risk project.

TBO4 is designed specifically to avoid this.

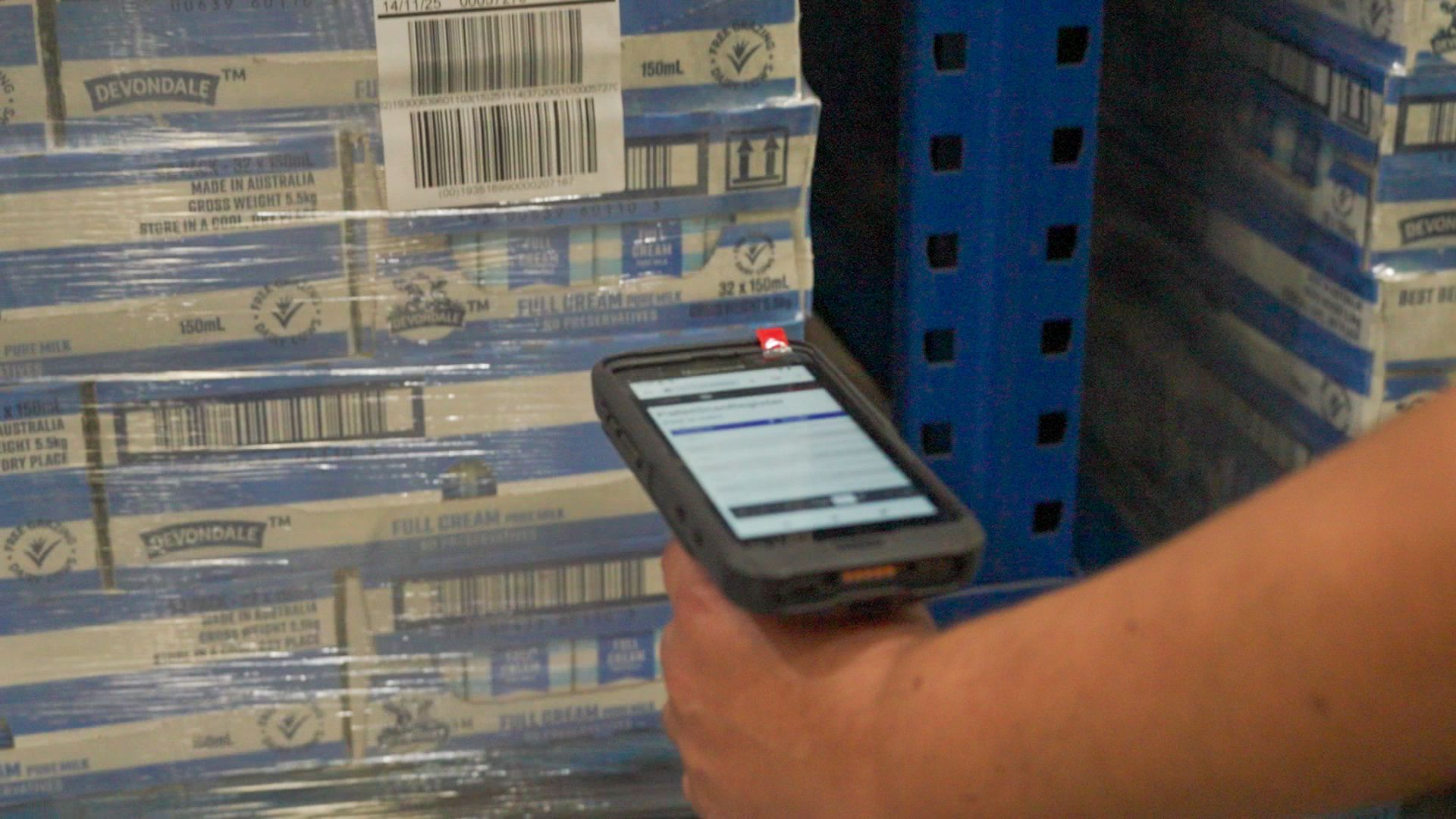

Our customers typically start with the core capabilities that deliver immediate value—such as receiving, real-time inventory control, picking, and dispatch—then progressively introduce additional functionality as the operation matures.

This might include:

- Advanced Putaway rules

- Advanced replenishment

- Labour tracking and productivity analytics

- Last mile integration

A phased approach reduces disruption, controls cost, and ensures each stage delivers a clear operational return.

Faster ROI through phased delivery

With TBO4, customers don’t wait years to see benefits.

A phased rollout allows warehouses to:

- Achieve efficiency gains early in the project

- Improve accuracy and throughput within weeks, not months

- Use operational savings to justify or fund later phases

- Reduce change fatigue for warehouse teams

- Scale the solution as volumes, channels, and automation increase

Instead of investing heavily upfront for a future-state operation, customers improve performance immediately and build momentum.

The hidden risk of waiting

While a phased WMS implementation delivers incremental improvement, doing nothing allows inefficiencies to compound every single day.

Manual processes become embedded. Informal workarounds turn into operational dependencies. New customers, SKUs, and channels are layered onto fragile foundations. By the time a WMS becomes unavoidable, the project is larger, riskier, and more expensive than it needed to be.

We often see that customers who delayed for years could have avoided significant cost and complexity by starting earlier—even with a limited initial scope.

Progress without overcommitment

A phased approach with TBO4 is not about over-investing—it’s about making controlled, commercially sensible progress.

Start with the functionality that delivers the greatest operational impact today. Stabilise the warehouse. Then extend the platform as requirements evolve.

This is how The RIC Group helps customers de-risk WMS investment while still achieving measurable, ongoing improvement.

Final thought

In warehouse operations, standing still is rarely neutral—it’s expensive.

Customers who move forward with TBO4 in a phased approach reduce risk, unlock efficiencies sooner, and avoid the compounding cost of inaction. The most successful WMS projects aren’t always the biggest or fastest—they’re the ones that start.

If your warehouse is under pressure, the real question isn’t whether you can afford to implement a WMS—it’s whether you can afford not to.