For the last decade, the warehouse conversation has been dominated by one thing: Outbound speed.

My thoughts on the 2026 WMS trend -

The conversation with WMS is normally dominated with questions of "How fast can we pick?" "How quickly can we pack?" "Can we meet the 2-day delivery promise?" "Can we have KPI's on picking and packing?"

While these questions are critical, I have been seeing a considerable shift late 2025 and into 2026. Our supply chain customers are telling us loud and clear that the bottleneck has moved. It’s no longer just about getting goods out the door—it’s about getting them in the door, on the shelf, and saleable faster than ever before.

You cannot have a high-speed outbound operation if your inbound receiving is stuck in the slow lane.

The Cost of the "Dock Door Bottleneck"

In many warehouses, receiving remains the most manual, paper-heavy process in the building. A truck arrives, a driver hands over a paper manifest, and your team spends hours counting boxes, cross-referencing purchase orders, and manually keying data into the ERP.

This creates a "blind spot" where inventory is physically in your building but digitally invisible. It’s sitting on the dock, but your sales team can’t sell it, and your pickers can’t pick it.

TBO4: Integrating Container Tracking & ASN Automation

At The RIC Group, we realised that fixing the supply chain also means fixing the start of the chain. To do that, you need more than just a scanner - you need visibility before the truck even arrives.

We have focused the development of our TBO4 WMS on solving the inbound puzzle by merging Container Tracking with ASN (Advanced Shipping Notice) Receiving.

1. Strategic Resource Alignment

Efficient inbound starts at the port, not the dock. By integrating container tracking, TBO4 gives businesses the foresight to:

- Predict Arrival Windows: Know exactly when a container is cleared and en route.

- Labor Optimization: Don't have a full team standing around waiting for a delayed container—or worse, being understaffed when three arrive at once.

- Space Management: Clear the staging areas and prep the racks based on the specific volume of the incoming shipment.

2. The Digital Handshake (ASN)

Once the container arrives, the transition to the shelf is seamless. Instead of reacting to a delivery, TBO4 allows your warehouse to "know" the contents down to the SKU level:

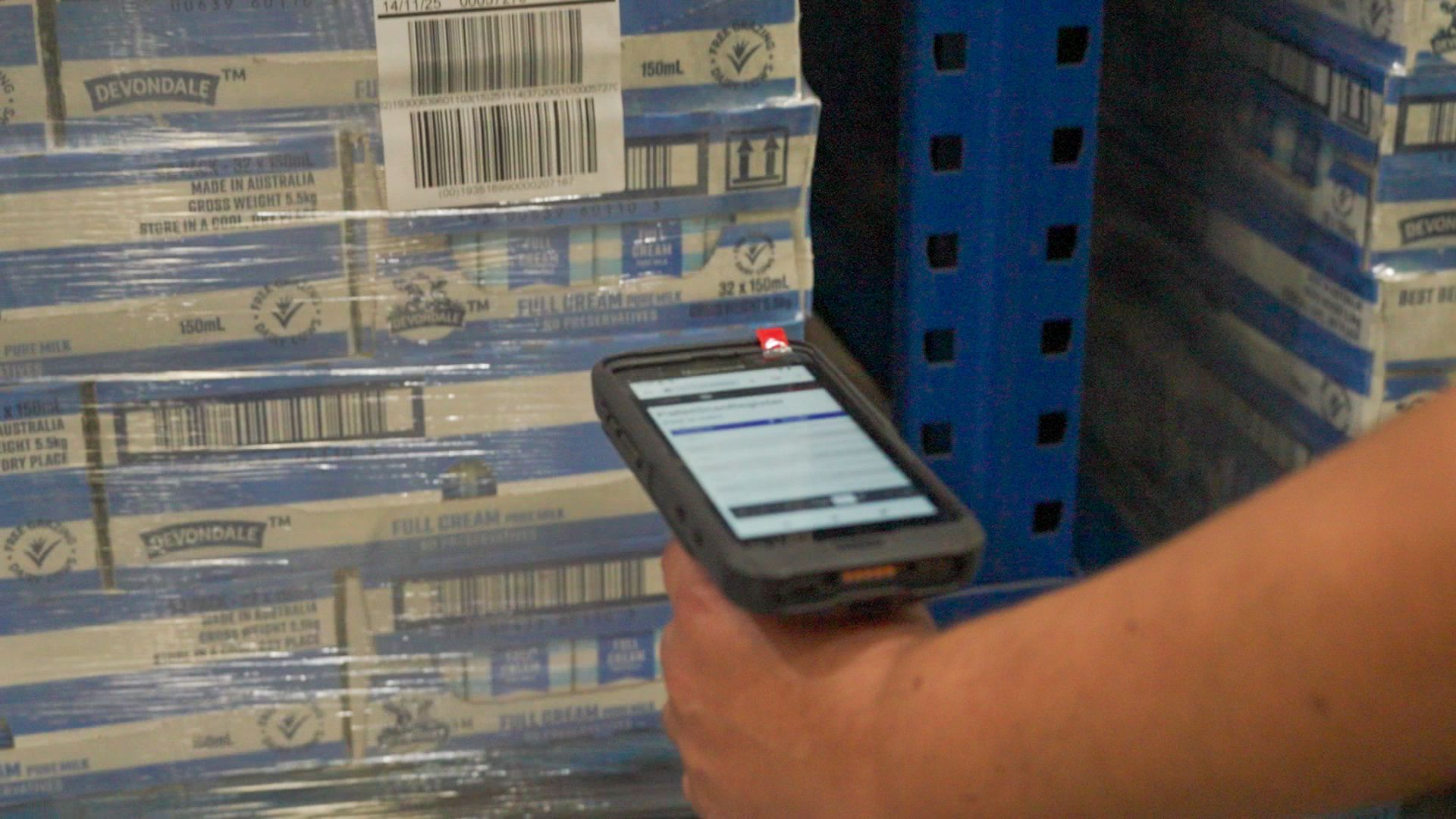

- Scan & Verify: When the pallet comes off the truck, your team simply scans the license plate (LPN) or the goods.

- Instant Reconciliation: TBO4 instantly compares what was scanned against the ASN.

- Exception Handling: Shortages or damages are flagged immediately—no manual counting or "guessing" later.

Why Our Customers Are Demanding This Now

The customers we speak with are tired of "double handling" data and the chaos of unscheduled arrivals. They want Dock-to-Stock time reduced from days to hours. By leveraging container tracking and ASN automation in TBO4, our clients are seeing:

- Immediate Visibility: Stock becomes "available to promise" the moment it is scanned on the dock.

- Resource Efficiency: Staffing levels are aligned with actual container arrival times, reducing overtime and idle time.

- Vendor Accountability: Irrefutable digital proof of exactly what was delivered versus what was ordered.

The Future is Inbound

If 2025 was about refining the pick path, 2026 is about perfecting the receiving dock. At The RIC Group, we are turning the idea of a "smart warehouse" into a reality where efficiency starts the moment the container leaves the port and continues until the goods are on the shelf.

Are you ready to eliminate the bottleneck at your receiving dock? Contact us today to see TBO4’s inbound and container tracking automation in action.