Understanding Time and Motion Testing

In the fast-paced world of warehouse management, efficiency is the cornerstone of success. Time and motion testing plays a crucial role in measuring and optimizing operational performance, particularly before and after the implementation of a Warehouse Management System (WMS). This structured approach provides valuable insights into productivity gains, process improvements, and cost savings.

Understanding Time and Motion Testing

Time and motion studies involve analyzing warehouse workflows to assess the duration of specific tasks and identify inefficiencies. This methodology helps establish benchmarks and highlights opportunities for automation and process refinement.

Key areas of focus in a warehouse setting include:

Picking and Packing – Evaluating the time taken to pick, pack, and prepare orders for shipment.

Putaway and Replenishment – Measuring efficiency in storing inbound stock and restocking pick faces.

Inventory Counts – Assessing the speed and accuracy of stocktaking.

Travel Time – Identifying unnecessary movements within the warehouse.

Error Rates – Analyzing incorrect picks, misplacements, and returns.

Time and Motion Testing Before WMS Implementation

Before a WMS is implemented, warehouses often rely on manual processes or outdated systems that create inefficiencies. Time and motion testing at this stage typically reveals:

Excessive Travel Time – Operators take indirect routes due to poor layout planning or lack of real-time location tracking.

High Error Rates – Manual data entry leads to mispicks, shipping errors, and inventory discrepancies.

Low Productivity – Staff spend significant time searching for stock or verifying orders.

Bottlenecks in Workflow – Picking and packing operations may suffer from congestion and delays due to paper-based processes.

By capturing these inefficiencies through detailed testing, businesses can quantify their impact and set performance improvement targets for the WMS implementation.

Time and Motion Testing After WMS Implementation

After deploying a WMS, another round of time and motion testing provides measurable evidence of performance improvements. Common expectations include:

Reduced Picking Time – Optimized picking routes and real-time stock visibility significantly cut down travel time.

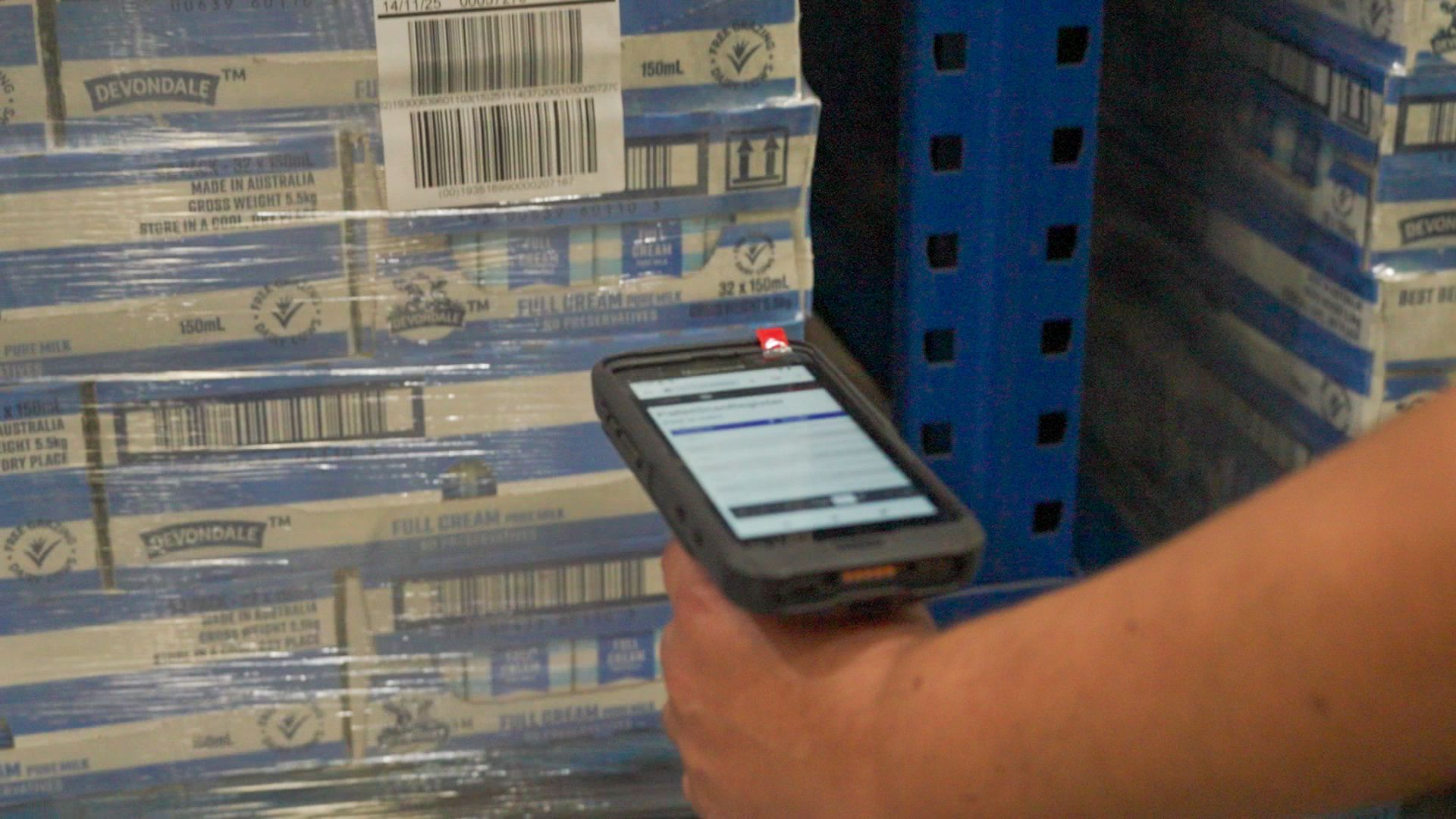

Enhanced Accuracy – Barcode scanning, RFID, and automation ensure near-perfect order accuracy.

Faster Putaway and Replenishment – System-driven putaway strategies minimize time spent locating storage locations.

Better Labor Utilization – Task prioritization and workload distribution improve efficiency and reduce idle time.

Decreased Returns and Rework – Improved order accuracy leads to fewer returns and customer complaints.

Setting Expectations for WMS Success

A well-implemented WMS should deliver significant efficiency gains, but the degree of improvement depends on factors like warehouse size, workforce adaptability, and system configuration. Based on time and motion test results, businesses can expect:

20-40% Reduction in Travel Time – System-guided workflows optimize movement.

25-50% Improvement in Order Accuracy – Automated validation reduces human errors.

30-60% Faster Order Processing – Streamlined processes and real-time inventory tracking enhance speed.

Conclusion

Time and motion testing is a powerful tool for assessing warehouse efficiency before and after WMS implementation. By measuring key performance indicators and setting realistic expectations, businesses can fully realize the benefits of a WMS, leading to a smarter, faster, and more cost-effective warehouse operation.

Experience a faster, smarter warehouse with TBO4 — our WMS is designed to guarantee a significant speed increase from order release to ERP update

Contact us as sales@thericgroup.com for more information.