Warehouse efficiency isn’t about working harder — it’s about working smarter. Many warehouses already have the people, space, and systems they need, but inefficiencies hide in disconnected processes, manual workarounds, and limited visibility.

True efficiency starts with understanding how work actually flows through the warehouse. Where are delays occurring? Which tasks are manual that could be automated? Are teams reacting to issues, or preventing them with real-time data?

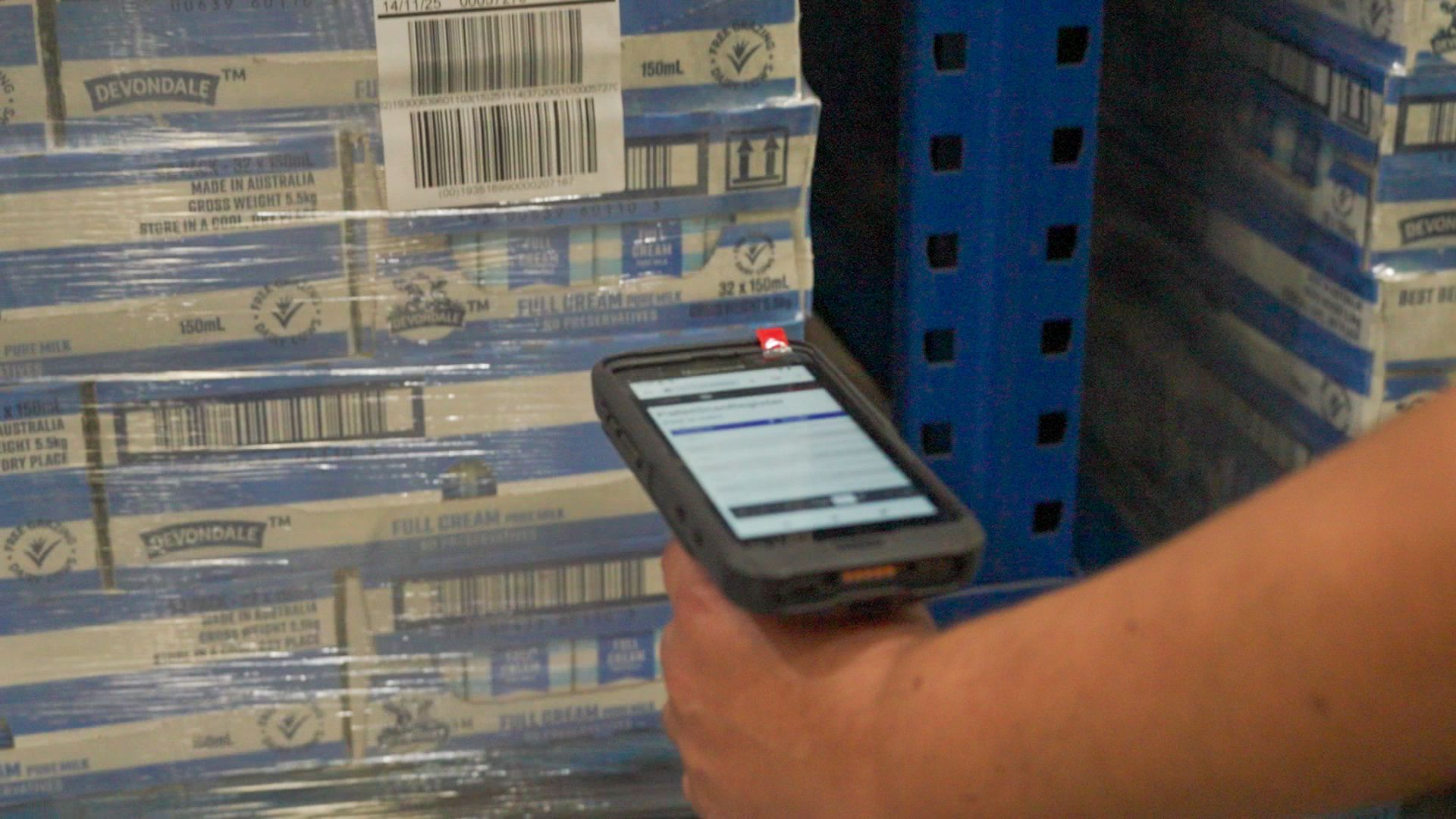

A modern WMS plays a critical role by:

- Eliminating double-handling and re-keying of data

- Providing real-time visibility across inventory, labour, and orders

- Standardising processes while still allowing flexibility

- Turning operational data into actionable insights

The result is faster throughput, fewer errors, better use of labour, and improved customer service — without necessarily increasing headcount or footprint.

In today’s supply chain environment, warehouse efficiency is no longer a competitive advantage — it’s a requirement. The warehouses that succeed are the ones that continuously measure, adapt, and optimise how work gets done.