Multi-Bin for MYOB EXO15/6/2017 The RIC Group's multi-bin is designed to provide advanced features and make warehouse management easy for MYOB EXO users. A WMS is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, put-away and picking.

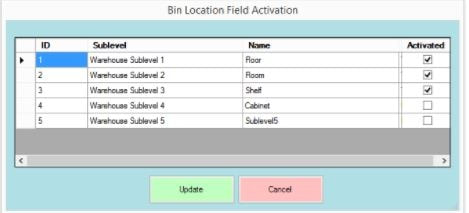

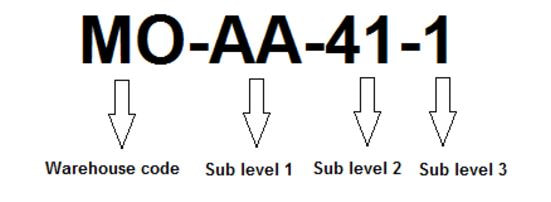

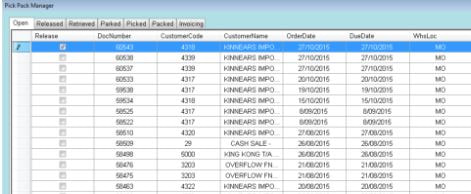

Our multi-bin for MYOB EXO helps manage the stock within the warehouse or warehouses, and enables seamless link to order processing and logistics management in order to pick, pack and ship products out of the warehouse more efficiently. The multi-bin has features of bin locations, quantity by bin location, directed picking, primary pick face, bulk bin locations, replenishment, licence plating, KPI reporting, wave batch picking and pack away. Let me run through some of the setup and features of our multi-bin for MYOB EXO. With our Multi-Bin for MYOB EXO the first thing the user will need to do is define the bin locations and what sub-level's you would like to define. Our WMS allows up to four sub levels. For example floor, zone, shelf, isle. Setting up your bin locations correctly, helps direct the picker to ensure shortest pick path when picking the sales order. The example of the bin locations is in the picture below of MO-AA-41-1. The next part to the multi-bin is you can add Zones. For example you may want to setup warehouse zones such as Light, Medium, Heavy. This adds the extra flexibility to allow the picker to pick the heaviest products first and then the lightest products last. Therefore this ensures the warehouse user stacks the pallet correctly when picking. Once the bin locations are all setup, you can use the warehouse management solution to do a stocktake by bin location to ensure you have accurate quantities by bin. The next process is using the Pick Pack Manager in the WMS to release sales orders. This can be done by wave as well. The operations manager releases the sales orders for picking and then it will follow each status through the process. Once released the PDA devices can retrieve the sales orders, and pick the correct products for the sales order. Each status will show the operations manager which sales orders are in process of being picked, which sales orders have been parked, which sales orders are getting packed, and which are ready to invoice. When the sales order has gone through the picking process, the operations manager can then select to invoice the order or orders. This will invoice the selected sales orders in MYOB EXO. What is important to note is the our multi-bin in MYOB EXO integrates with MYOB EXO in real time. MYOB EXO keeps all the stock on hand figures, however, our multi-bin keeps the quantity by bin figures, as MYOB EXO does not have this feature. The multi-bin has features of replenishment for primary pick face bins, and also KPI reporting for picker statistics and bin location heat map. We have our multi-bin WMS implemented at many sites using MYOB EXO and if you would like further information please contact us on [email protected] Comments are closed.

|

Archives

June 2024

|

Call Us: +61 466 368 934

- Home

-

Solutions

-

Advanced Logistics

>

- Advanced Logistics for Acumatica

- Advanced Logistics for SAP Business One

- Advanced Logistics for Odoo

- Advanced Logistics for Netsuite

- Advanced Logistics for Business Central

- Advanced Logistics for Sage Intacct

- Advanced Logistics for MYOB Acumatica

- Advanced Logistics for MYOB EXO

- Advanced Logistics for S/4 HANA

- Advanced Logistics for Sage 300

- Advanced Logistics for Tencia

- Advanced Logistics for Oracle Cloud ERP

- Transport Management System

- Last Mile Delivery

- Warehouse 3D Digital Twin

- RFID

- AUTONOMOUS MOBILE ROBOTS

-

Advanced Logistics

>

- Support

- Blog

- Success Stories

- About

- Contact Us