RFID in the warehouse15/11/2023 RFID technology has emerged as a valuable asset in optimizing supply chain management processes. Its ability to provide real-time visibility, automate data capture, and enhance accuracy has positioned it as a key enabler for efficient operations. With RFID, companies can streamline inventory management by tracking products throughout the supply chain, enabling better control over stock levels and reducing the risk of errors associated with manual tracking. The automated nature of RFID not only accelerates processes such as receiving and shipping but also contributes to minimizing shrinkage and loss through precise, real-time monitoring. Additionally, RFID facilitates efficient traceability, supporting compliance with regulations and providing crucial data for quality control.

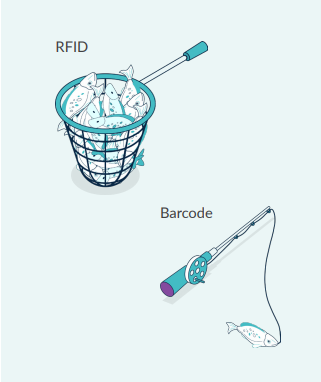

The analogy of fishing with a rod versus using a net effectively captures the essence of the differences between RFID and barcodes. Barcodes, akin to fishing with a rod, involve the sequential scanning of individual items, much like catching one fish at a time. On the other hand, RFID, likened to scooping all the fish up in a net, allows for simultaneous reading of multiple items, offering advantages in terms of speed and efficiency. Importantly, the decision to use RFID or barcodes isn't always a strict either-or scenario. There are numerous situations where a combination of both technologies can be employed to create a more versatile and effective solution. Barcodes, with their simplicity and established systems in various industries, are well-suited for applications that don't demand simultaneous scanning. However, their reliance on a direct line of sight can be a limitation. In contrast, RFID shines in scenarios requiring bulk reading, non-line-of-sight capabilities, or real-time tracking. The ability to read multiple tags at once and the flexibility in reading through obstacles make RFID ideal for applications where efficiency and visibility into large quantities of items are crucial. The RIC Group builds solutions which allow the combining of both technologies. This strategically can leverage the strengths of each, providing a comprehensive solution to diverse operational requirements. Please contact us to find out more. Comments are closed.

|

Archives

June 2024

|

Call Us: +61 466 368 934

- Home

-

Solutions

-

Advanced Logistics

>

- Advanced Logistics for Acumatica

- Advanced Logistics for SAP Business One

- Advanced Logistics for Odoo

- Advanced Logistics for Netsuite

- Advanced Logistics for Business Central

- Advanced Logistics for Sage Intacct

- Advanced Logistics for MYOB Acumatica

- Advanced Logistics for MYOB EXO

- Advanced Logistics for S/4 HANA

- Advanced Logistics for Sage 300

- Advanced Logistics for Tencia

- Advanced Logistics for Oracle Cloud ERP

- Transport Management System

- Last Mile Delivery

- Warehouse 3D Digital Twin

- RFID

- AUTONOMOUS MOBILE ROBOTS

-

Advanced Logistics

>

- Support

- Blog

- Success Stories

- About

- Contact Us